El residuo de soda es el barro residual proveniente del proceso de producción de plantas de soda de amoníaco. El residuo de Soda tiene un gran daño para el medio ambiente ecológico. El tratamiento de los residuos de soda para las empresas de producción de soda de amoníaco ha sido un problema muy difícil para muchas empresas. Esto restringe la aplicación del proceso de soda de amoníaco en la industria. La producción de residuos de soda es del 30% al 35% de la producción de producto. Ahora con el desarrollo nacional y en el extranjero para la protección del medio ambiente, la planta de refrescos está constantemente buscando la utilización de los recursos para los residuos de soda. El tratamiento de desechos de la planta de soda protegerá el medioambiente y ahorrará costos de procesamiento, en consecuencia, ayuda a la empresa a crecer de forma constante a largo plazo.

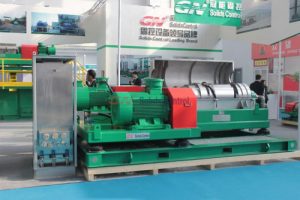

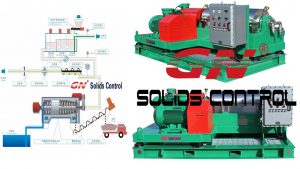

El equipo de separación de control sólido GN, el equipo de procesamiento relacionado con centrífugas puede resolver de manera eficiente los problemas de deshidratación de residuos de plantas de sosa. La centrífuga de GN se ha convertido en el equipo básico para el tratamiento de los residuos de plantas de soda. En comparación con otros equipos de tratamiento, la centrífuga decantadora de GN tiene las siguientes ventajas:

- La centrífuga de GN para el tratamiento de residuos de soda tiene las ventajas de una instalación pequeña y conveniente.

- Mediante el control del programa PLC, el equipo de GN puede funcionar de forma continua y la operación es simple.

- En comparación con otros equipos, la centrífuga de GN tiene una mayor capacidad de producción de lodo y un menor consumo de energía.

- Debido al bajo costo de mantenimiento, las centrífugas de GN reducen en gran medida el costo del tratamiento de desechos.

- Toda la arena residual de destilación convencional puede separarse mediante una centrífuga y no afectará la capacidad del equipo.

- La red de servicio de marketing global, puede proporcionar un servicio más oportuno para las empresas de refrescos en diversas regiones.